-

Product DescriptionCompany Info.<>

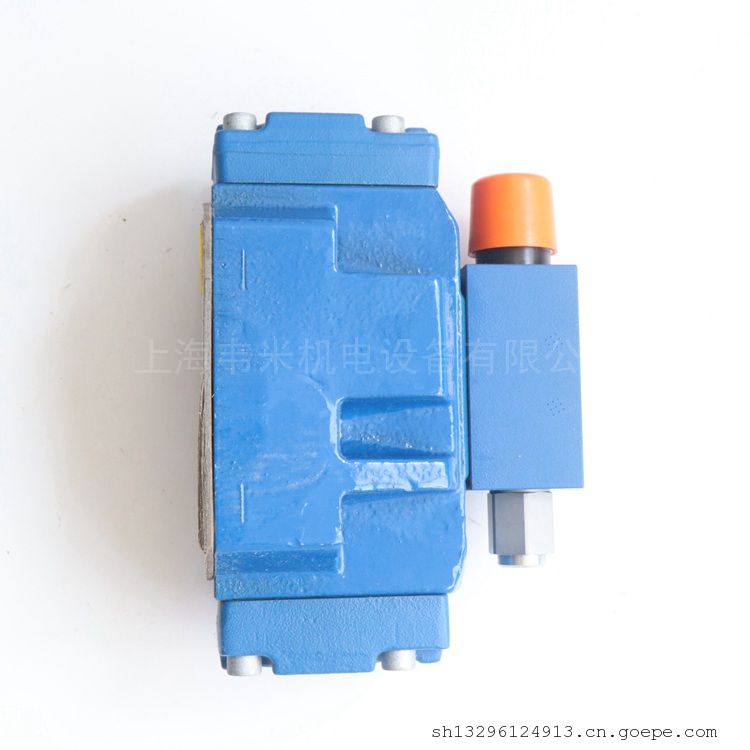

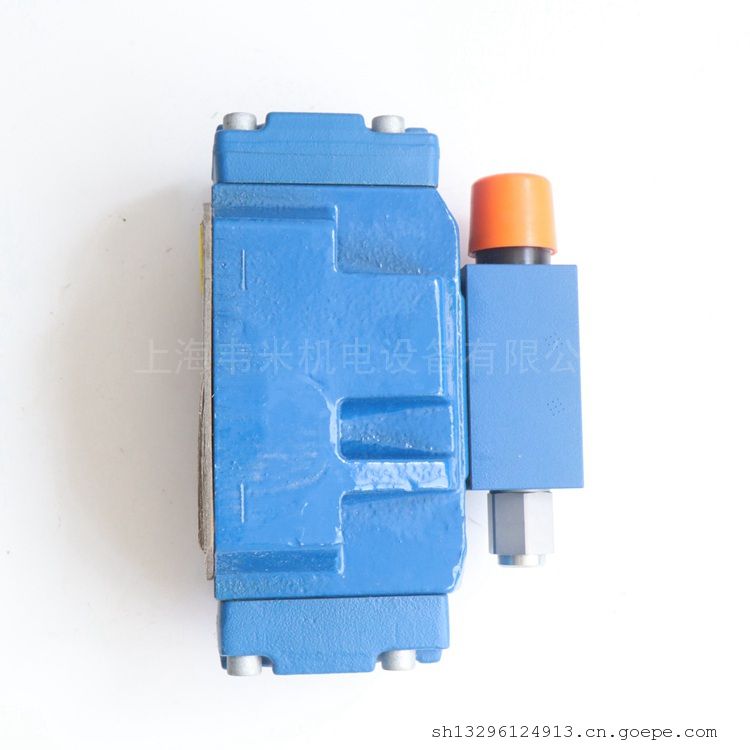

- Model:

- R900917775 3DR16P5-53/250Y/00M

- Processing customization:

- No

- Connection form:

- Screw thread

- Material:

- Cast iron

- Nominal diameter:

- 16 mm

- Applicable medium:

- Oil product

- Sealing form:

- Soft seal type

- Standard:

- debiao

- Shape:

- Small size

- Flow direction:

- One-way

- Driving mode:

- hydraulic

- Parts and accessories:

- Valve body

- Use:

- Pressure reducing valve

- Pressure environment:

- Normal pressure

- Operating temperature:

- Normal temperature

Rexroth pilot pressure relief valve R900917775 3DR16P5-53/250Y/00M, Shanghai Weimi Mechanical and Electrical Equipment Co., Ltd. Main supply products, product pictures in kind shooting, original factory, warranty for one year, a large number of products in stock supply, price concessions Quick quote, Contact: Lei Qing. Welcome to purchase!

Rexroth REXROTH pilot operated pressure reducing valve

Type 3DR

characteristic

- Valves for reducing (P to A) and limiting (A to T) system pressures

- For base plate mounting

- Port mounting surface according to ISO 4401-07-07-0-05

- Base plate in accordance with sample RC45056 (ordered separately)

-4 pressure levels

-4 adjusting elements, optional:

- Knob.

- Hexagon sleeve and protective cap

- With graduated lockable knob

- Dial knob

function

Type 3DR pressure control valves are pilot-operated three-way pressure reducing valves with relief function for secondary circuits. They are used to reduce system pressure.

Pressure relief valve is mainly composed of a main valve with a control spool and a pilot control valve with a pressure regulating element.

In the starting position, the valve is open. Hydraulic oil can flow from passage P to passage A without any restriction. The pressure in passage A is applied through the bore to the area of the spool opposite the compression spring. At the same time, pressure is applied to the spring-loaded side of the control spool through the orifice and to the ball of the pilot control valve through the passage.

Depending on the setting of the compression spring, hydraulic pressure builds up upstream of the ball and in the conduit and holds the control spool in the open position. Hydraulic oil flows from passage P through the control spool to passage A until the pressure in passage A increases above the pressure set by the compression spring and lifts the ball. Control spool movement to closed position. When the pressure in passage A reaches equilibrium with the pressure value set by the compression spring, the desired pressure reduction is achieved. When an external force acting on the actuator causes a further increase in pressure in passage A, the control spool is further compressed compressing the compression spring. This opens the connection between passage T and passage A through the control port on the control spool. The amount of hydraulic oil drained to the tank ensures that the pressure does not increase. Pilot oil always leaks from the spring chamber through the pilot line to port Y. Always keep pilot oil returning to the tank at zero pressure. The reduced pressure in passage A can be checked using the pressure gauge port.

technical data

Weight 8kg

Installation position optional

Ambient temperature range –30 to +50° C

hydraulic pressure

Nominal pressure 315bar

work stress

Port P 315bar

Port A 250bar

Port Y alone, pressure-free to tank

pressure setting–

Small bar depending on flow

Large bar 50; 100; 200; 250

Flow rate 220l/min

Hydraulic oils Mineral oils (HL, HLP) according to DIN 51524 (for NBR and FKM seals); rapidly biodegradable hydraulic oils according to VDMA 24568 (see also RC 90221);HETG (rapeseed oil)(for NBR and FKM seals);HEPG (polyethylene alcohol)(for FKM seals only);HEES (synthetic esters)(for FKM seals only); other hydraulic oils available on request

Hydraulic oil temperature range

–30 to +80° C (NBR seals)

–20 to +80° C (FKM seals)

Viscosity range 10 to 800 mm2/s

* Maximum permissible contamination of hydraulic oil-Cleanliness class 20/18/15 according to ISO 4406 (c)(Cleanliness class of specified components must be observed in hydraulic systems. Effective filtration prevents failures and extends component life.)) For filter selection, see samples RC 50070, RC 50076, RC 50081, RC 50086, RC 50087 and RC 50088.

German Rexroth REXROTH pilot operated pressure reducing valve Order Nos. and models:

R900917775 3DR16P5-53/250Y/00M

Rexroth REXROTH Pilot operated proportional relief valve with integrated electronics (OBE)

R901344448 DBEME10-71/315YG24K31A1M

DBEME

Component series 7x

High working pressure 350 bar

Pilot operated valve for limiting system pressure

Controlled by proportional electromagnets

For base plate mounting and threaded connections: Port mounting surface according to ISO 6264

high pressure limit

Valve and control electronics are from the same family

SetPoint Manufacturing tolerances for pressure characteristic curves Integrated electronic components (OBE) with small tolerances

function

The DBEM valve is a pilot operated relief valve with integrated electronics (OBE). These valves are used to limit the working pressure of hydraulic systems. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The basic components of these valves include a housing with a main spool, a superposition valve with a large pressure limit, and a proportional pilot control valve. The proportional electromagnet is also equipped with a housing with control electronics. Apply the supply voltage and control value voltage to the connector. The pressure characteristic curve of the control value is adjusted to very low manufacturing tolerances at the factory.

Model DBEME...

Pressure applied in passage P acts on the main spool. At the same time, pressure at port P is applied to the spring-loaded side of the main spool through the control circuit with nozzle. Pressure is also applied to the frame of the proportional pilot control valve through the connecting bore. The hydraulic pressure at the pilot seat overcomes the proportional solenoid control value-dependent force. If the hydraulic pressure exceeds the coil magnetic force, the pilot seat opens. Pilot oil can now flow through the control circuit to port Y and to the tank; therefore, a pressure drop occurs at the main spool on the control circuit. Release the connection from port P to T. The main spool controls the set operating pressure at port P.

Spring-loaded relief valves are integrated since hydraulic protection prevents abnormally high pressure values. This high pressure limit is a preset value based on the relevant pressure level. Within the valve operating range, the spring holds the valve holder to the valve seat and the valve core closes thereby.

If the pressure at the main spool spring chamber exceeds the valve's maximum allowable set point pressure, the carrier will press against the compression spring and the connection to the spring chamber will open. Pilot oil flows into the tank through port Y. Due to the presence of the control circuit, a pressure drop occurs at the main spool. Release the connection from port P to T. The main spool controls the large operating pressure set at port P. If necessary, the preset pressure can also be reduced by means of an adjusting element. Port Y must be connected from the outer tube to the tank. The tank must be connected after pressure relief. The valve can be unloaded or high pressure limited through port X.

REXROTH Direct acting proportional relief valve without integrated electronics (OBE)

R901000848 DBET-62/350G24K4V

DBET

strength 6

Component Series 6X

High working pressure 420 bar

High flow rate 2 l/min

Direct-acting valves are used to limit system pressure

operated by proportional electromagnet

Proportional electromagnet with centering thread and detachable coil

For base plate mounting: hole diagram according to ISO 4401

Modular amplifier design, European board format and as plug-in amplifier

Individually adjustable up and down ramps, control values Pressure characteristic curves can be finely adjusted

The DBET Proportional Relief Valve is a remotely controlled valve with a seated design that can be used to limit system pressure. Operates with proportional electromagnet with centering thread and detachable coil. The inside of the coil is connected to port T or Y and filled with hydraulic oil. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The valve is mainly composed of shell, proportional electromagnet, valve seat and valve frame.

fundamental

To set the system pressure, control the value at the control electronics. The electronics drive the solenoid with current according to the control value. The proportional electromagnet converts the current into mechanical force, which acts on the valve frame through the armature plunger. Push the valve holder into the valve seat and block the connection between port P and T or Y. If the hydraulic pressure on the carrier is equal to the coil magnetic force, the valve controls the set pressure by lifting the carrier off its seat, allowing hydraulic oil to flow from port P to T or Y. If the control value is zero, the control electronics apply only a small control current to the proportional electromagnet and a small constant pressure is also set.

Rexroth REXROTH Direct acting proportional relief valve with integrated electronics

DBETE

R901045246 DBETE-62/315G24K31F1V

R901121103 DBETE-62/420G24K31F1V

strength 6

Component Series 6X

High working pressure 420 bar

High flow rate 2 l/min

Direct-acting valves are used to limit system pressure

operated by proportional electromagnet

Proportional electromagnet with centering thread and detachable coil

For base plate mounting: hole diagram according to ISO 4401

SetPoint Manufacturing tolerances for pressure characteristic curves are small

Proportional Relief Valve Type DBETE is a remotely controlled valve with seat design and integrated electronics for limiting system pressure. Operates with proportional electromagnet with centering thread and detachable coil. The inside of the coil is connected to port T or Y and filled with hydraulic oil. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The valve is mainly composed of housing, proportional electromagnet, valve seat, valve frame and integrated electronic components. Apply the supply voltage and control value voltage to the connector. The pressure characteristic curve of the control value is adjusted to very low manufacturing tolerances at the factory.

fundamental

To set the system pressure, control the value at the control electronics. The electronics drive the solenoid with current according to the control value. The proportional electromagnet converts the current into mechanical force, which acts on the valve frame through the armature plunger. Push the valve holder into the valve seat and block the connection between port P and T or Y. If the hydraulic pressure on the carrier is equal to the coil magnetic force, the valve controls the set pressure by lifting the carrier off its seat, allowing hydraulic oil to flow from port P to T or Y. If the control value is zero, the control electronics apply only a small control current to the proportional electromagnet and a small constant pressure is also set.

Rexroth REXROTH Pilot Proportional Pressure Reducing Valve

DRE, DREE

R900932943 DRE6-11/100MG24K4M

0811402055 DRE6X-11/175MG24-8NZ4M

strength 6

Component Series 1X

High working pressure 210 bar

High flow rate 30 l/min

Connection Type Base Plate Installation

Port mounting surface ISO 4401-03-02-0-05

Installation position arbitrary

Ambient temperature range -20… +70℃

Storage temperature range -20… +80℃

Degree of protection according to EN 60529 IP65 (if a suitable and correctly installed connection plug is used)

Compliance CE EN 61000-6-2 and EN 61000-6-3 checked according to EMC Directive 2014/30/EU

Hydraulic oil temperature range -20… +80℃

Viscosity range 15… 380mm²/s

Large permissible contamination of hydraulic oil, cleanliness class 20/18/15 according to ISO 4406 (c)

Pilot flow 0.65l/min

High flow rate 30l/min

Mineral oil HL, HLP

Suitable sealing materials NBR, FKM

Lag ± 2.5%

Repeatability <±2%

Linearity ± 3.5%

Manufacturing tolerance of pressure characteristic curve of control value ± 2-3%

Step response ≈ 150ms

Power supply 24VDC

Small control current 100mA

Large control current 1600mA

resistance of electromagnetic coil

Low° temperature value at 20 C 5Ω

High temperature 7.5Ω

Duty cycle 100%

Current consumption 1.5A

External safety device 2A. time delay

import

Voltage 0… 10V

Current 4… 20mA

For pressure relief in connection A (with pressure limiting device)

Operated by proportional electromagnets

For base plate mounting

Oil port mounting surface according to ISO 4401-03-02-0-05

When operating with external control electronics, manufacturing tolerances of the setpoint pressure characteristic curve are small by means of electrical regulation

Minor constant pressure in connection A

With integrated electronics (OBE), optional

CE compliant with EMC Directive 2014/30/EU

DRE(E) valves are electronically controlled pilot operated three-way pressure reducing valves that provide pressure limitation for electrical appliances. This valve is used to reduce system pressure.

The valve basically consists of a pilot control valve, a proportional magnet, and a main valve with a main control spool.

Model DRE

The pressure to be reduced is adjusted in channel A according to the setpoint value by means of a proportional magnet.

When using the relieved port P, the spring holds the main control spool in the initial position.

thereby opening the A to T connection and blocking the P to A connection.

Pressure connection from connection P to annular channel.

Pilot oil flows from the bore to connection T, through the flow regulator, through the nozzle to the pilot control valve, through the restriction gap to the longitudinal groove and bore.

decompression

Pilot pressure builds up in the control chamber as a function of the setpoint.

Move the main control spool to the right and hydraulic oil flows from P to A.

The consumer pressure is established in connection A of the spring chamber via the channel and the nozzle.

Raise the pressure in port A to the set pressure of the pilot control valve, which causes the main control spool to move to the left. The pressure in port A is approximately the same as the set pressure of the pilot control valve.

pressure limit

If the pressure in port A exceeds the set pressure of the pilot control valve, the main control spool continues to move to the left.

thereby breaking the connection from A to T and limiting the pressure generated in interface A to the set point.

DREE– with integrated electronics (OBE)

These valves conform to DRE type both functionally and structurally. The proportional magnet is also fitted with a housing with control electronics.

Connect mains voltage and setpoint voltage or setpoint current via device plug.

Fine-tune the setpoint pressure characteristic curve at the factory with a small sample deviation.

Rexroth REXROTH Pilot Proportional Pressure Reducing Valve

DRE(M) 10, DRE(M) 20

R901279577 DREM10-61/200YG24-8K4M

Size 10, 25

Component Series 6X

High working pressure 315 bar

High flow rate 300 l/min

Installation position arbitrary

Weight 4.7kg 6kg

Storage temperature range -20… +80℃

Ambient temperature range -20… +70℃

Pilot flow 0.8l/min

High flow rate 200l/min 300l/min

Hydraulic oil temperature range -20… +80℃

Viscosity range 15… 380mm²/s

Large permissible contamination of hydraulic oil, cleanliness class 20/18/15 according to ISO 4406 (c)

Lag ± 3.5%

Repeatability <±2%

Linearity ± 2%

Manufacturing tolerance of pressure characteristic curve of control value ± 3.5

Step Response 10... 90% ≈ 130ms

characteristic

Valve for reducing system pressure

Operated by proportional electromagnets

Proportional electromagnet with rotatable and detachable coil

For base plate mounting: port mounting surface according to ISO 5781

Third oil path A to Y (φ7.5 mm)

Linearized pressure/setpoint characteristic curve

Good transient response

Optional check valve can be installed between A and B

Optional high pressure limit

DRE(M) valve is a pilot operated pressure reducing valve. These valves can be used to reduce operating pressure.

The basic components of these valves are a pilot control valve with proportional solenoid, a main valve with main spool, and an optional check valve.

Model DRE...

The pressure in channel A can be set according to the control value by means of proportional electromagnets.

The spring holds the main spool in its initial position at rest, i.e., when there is no pressure in passage B. The connection from channel B to channel A is closed. Therefore, start-up jumps can be avoided.

Pressure applied in passage A acts on the face of the main spool through the bore. Pilot oil flows from passage B through the orifice to constant current control, which keeps pilot flow constant regardless of the pressure drop between passages A and B. pilot flow

The constant current control flows into the spring chamber, through the holes and, through the valve seat, into passage Y and back from there. Preset the desired pressure in channel A via the associated amplifier. The proportional solenoid moves the valve carrier toward the seat and limits the pressure in the spring chamber to the set value. If the pressure in passage A is below the preset control value, the higher pressure in the spring chamber will shift the main spool to the right. The connection from B to A is open. If the setpoint pressure at A has been reached, the forces at the main spool are balanced-the main spool is in the control position.

Pressure at spool end of channel A = spring force at spool end of spring chamber–

If the pressure at A (e.g.) is to be reduced in a vertical hydraulic cylinder (e.g. cylinder piston in cut-off position), a lower control value can be preset via the control electronics, so that the lower pressure value is preselected and immediately appears in the spring chamber. The higher pressure value acting on the main spool surface at A pushes the main spool toward the protection plug to the OFF position. The connection A to B is blocked and the connection A to Y is open. The force at the spring is now opposed to the hydraulic force acting on the main spool surface. At this main spool position, hydraulic oil can flow from passage A through the control edge to Y into return.

When the pressure at A drops to the sum of the pressure in the spring chamber and p of the spring, the main spool closes the large control orifice in the socket at control edge A to Y.

The residual pressure difference with respect to the new control value at A is approx. 10 bar and the current pressure can only be relieved via the control orifice. This results in a good transient response without pressure undershoot. In order to achieve free backflow from channel A to channel B, a check valve can be optionally installed. Part of the charge flow at passage A can also flow back through the open main spool A to Y control edge.

Model DREM...

In order to provide hydraulic protection against excessive pressure at port A due to impermissible high electrical control currents on the proportional solenoid, a spring-loaded relief valve may optionally be installed to limit high pressures. This high pressure limit is preset based on the relevant pressure level.

Rexroth REXROTH Pilot Proportional Relief Valve

(Z)DBE 6, (Z)DBEE 6

R901335463 ZDBEE6VP2-21/315G24K31A1M

strength 6

Component Series 2X

High working pressure 350 bar

High flow rate 30 l/min

Installation position arbitrary

Weight 2.5kg

Storage temperature range -20… +80℃

Ambient temperature range -20… +70℃

Return Pressure Return Pressure Port A, External Pilot Oil

High flow rate 30l/min

Hydraulic oil temperature range -20… +80℃

Viscosity range 15… 380mm²/s

Large permissible contamination of hydraulic oil, cleanliness class 20/18/15 according to ISO 4406 (c)

Lag ± 3%

Repeatability <±2%

Linearity ± 3.5%

Manufacturing tolerance of control value pressure characteristic curve, related to hysteresis characteristic curve and pressure increase

Hydraulic oil HL, HLP

Suitable sealing material NBR/FKM

Large coil current 1760mA

electromagnetic coil resistance

Low° temperature value 5.5 at 20 C Ω

High temperature value 8.05Ω

Duty cycle 100%

Power supply 24VDC

characteristic

Pilot operated proportional valve to limit system pressure opens and relieves pressure to return to tank

operated by proportional electromagnet

Proportional electromagnet with rotatable and detachable coil

For base plate mounting or superimposed valve plate design: port mounting surface according to ISO 4401-03-02-05 and DIN24340

Valve and control electronics are from the same family

External control electronics for models DBE and ZDBE

Linearized pressure/setpoint characteristic curve

Models DBEE and ZDBEE with integrated electronics (OBE)

SetPoint Manufacturing tolerances for pressure characteristic curves are small

(Z) Type DBE pilot-operated proportional relief valve is activated by proportional solenoid. This valve can be used to limit system pressure. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The basic components of these valves are the pilot control stage and the main stage. The pilot control assembly consists of a proportional solenoid, a frame, and a seat. The main stage consists of a housing and main spool assembly. Proportional electromagnets convert electrical current proportionally into mechanical force. An increase in current results in a corresponding increase in coil magnetism. The system pressure can be set according to the control value via proportional electromagnets. The pressure applied by the system to passage P acts on the right side of the main spool assembly. At the same time, system pressure will act on the spring-loaded side of the spool through the control circuit equipped with the nozzle. Through the seat of the pilot line, the pressure at the spring chamber frame overcomes the force of the proportional solenoid. When the pressure reaches a preset value, the valve frame is lifted from the seat. Pilot oil (depending on the model) can now drain either to the outside through port A (Y) or to the internal tank, which also limits the pressure on the spring-loaded side of the main spool. If system pressure continues to ramp up, high pressure on the right side of the spool will push the spool to the left to the P to T control position. At small control currents (corresponding to zero control values), the small setpoint pressure will be set.

Watch out!

Prevent empty tank line operation. A preload valve (preload pressure approx. 1 bar) must be installed under the appropriate installation conditions.

Model (Z)DBEE pilot-operated proportional relief valves are activated by proportional solenoids. This valve can be used to limit system pressure. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The basic components of these valves are the pilot control stage and the main stage. The pilot control assembly consists of a proportional solenoid, a frame, and a seat. The proportional electromagnet is also equipped with a housing with control electronics. Apply the supply voltage and control value voltage to the connector. The pressure characteristic curve of the control value is adjusted to very low manufacturing tolerances at the factory. The main stage consists of a housing and main spool assembly. Proportional electromagnets convert electrical current proportionally into mechanical force. An increase in current results in a corresponding increase in coil magnetism. The system pressure can be set according to the control value via proportional electromagnets. The pressure applied by the system to passage P acts on the right side of the main spool assembly. At the same time, system pressure will act on the spring-loaded side of the spool through the control circuit equipped with the nozzle. Through the seat of the pilot line, the pressure at the spring chamber frame overcomes the force of the proportional solenoid. When the pressure reaches a preset value, the valve frame is lifted from the seat. Pilot oil (depending on the model) can now drain either to the outside through port A (Y) or to the internal tank, which also limits the pressure on the spring-loaded side of the main spool. If system pressure continues to ramp up, high pressure on the right side of the spool will push the spool to the left to the P to T control position. At small control currents (corresponding to zero control values), the small setpoint pressure will be set.

Watch out!

Prevent empty tank line operation. A preload valve (preload pressure approx. 1 bar) must be installed under the appropriate installation conditions.

R901304331 DBE6-21/100G24K4M

Rexroth REXROTH Direct acting directional slide valve with electromagnetic activation

WE 6... E

strength 6

Component Series 6X

High working pressure 350 bar

High flow rate (DC) 80 l/min

High flow rate (AC) 60 l/min

Three-position four-way, two-position four-way or two-position three-way model

Oil port mounting surface according to ISO 4401-03-02-0-05 (with or without holes)

High power coil, optional rotation 90°

Electrical connections as single or centered connections

Auxiliary controls, optional

Spool position monitoring, optional

CE>> compliance with Low Voltage Directive 2014/35/EU at 50 VAC or 75 VDC

Solenoid coil is an approved component with UR marking to UL 906, version 1982, optional

CSA certified, optional

The directional valve for WE models is a solenoid operated directional spool valve that can be used as a solenoid assembly. They are used to control the start, stop and direction of flow.

The directional valve basically consists of a housing, one or two electromagnets, a control spool and a return spring.

In the de-energized state, the control spool is held in the neutral or initial position by the return spring (except version O).

When the electromagnet in the hydraulic oil is switched on, the control spool is moved from its rest position to the desired end position. This signals the desired flow direction based on the selected symbol.

When the solenoid is switched off, the control spool is pushed back to the neutral or initial position (except valves with OF and valves without spring type O

Auxiliary operation allows manual switching of the valve without energizing the magnet.

The hydraulic system must be properly vented to ensure proper operation.

Without spring return" O" (symbols A, C and D only)

This model is a directional valve with two switching positions and two electromagnets without actuator. Valves without spring return at the control spool have no defined initial position in the de-energized state.

Without spring return, with device" OF" (symbols A, C and D only)

This model is a directional valve with two switch positions and two electromagnets with actuators. The control valve core is fixed in the corresponding switching position through the device. Therefore, no current needs to be applied to the electromagnet during operation, which contributes to energy-saving operation.

Model 73... A12" (soft handoff behavior)

The combination of control spool and solenoid reduces the number of reversing strokes that occur when the valve opens or closes. The reversing stroke (measured as acceleration value a) can be reduced by approximately 85% compared to standard valves, depending on the type of control spool (see acceleration value).

Note:

Pressure spikes in drain lines connecting two or more valves may cause unintended control spool movement on models with actuators. It is recommended to lay a separate return line or install a check valve in the drain line.

Due to the design principle, internal leakage occurs in the valve, and the leakage volume increases during the service life.

throttle insert

Depending on the prevailing operating conditions, throttle inserts will be required if flow exceeding the performance limits of the valve is likely to occur during switching.

German Rexroth REXROTH solenoid valve Order No. and model:

R900561180 3WE6A62/EG24N9K4

R900915873 3WE6A62/EG24N9K4/V

R900935575 3WE6A62/EG220N9K4/V

R900915672 3WE6A62/EW230N9K4

R978017740 3WE6A6X/EG24N9K4/62

R900948958 3WE6B62/EG24N9K4/V

R900907814 3WE6B9-62/EG24N9K4

R900561272 4WE6C62/EG24N9K4

R900901748 4WE6C62/EW110N9K4

R900908879 4WE6D62/EG110N9K4

R900944594 4WE6D62/EG110N9K4/V

R900561274 4WE6D62/EG24N9K4

R900564105 4WE6D62/EG24N9K4/V

R900908590 4WE6D62/EG24N9K4/B12

R900903081 4WE6D62/EG205N9K4

R900916984 4WE6D62/EG220N9K4

R901008688 4WE6D62/EG220N9K4/V

R900551704 4WE6D62/EW110N9K4

R900909559 4WE6D62/EW230N9K4

R901483086 4WE6D62/OFEG110N9K4/B12

R900567512 4WE6D62/OFEG24N9K4

R900903465 4WE6D62/OFEG24N9K4/V

R900920691 4WE6D62/OFEG220N9K4

R900922533 4WE6FB62/EG24N9K4

R900567997 4WE6J73-62/EG24N9K4/A12

R900931967 4WE6JA62/EG24N9K4/B08

R900903463 4WE6L62/EG24N9K4/V

R900577475 4WE6M62/EG24N9K4

R900571012 4WE6R62/EG24N9K4

R900905896 4WE6Y62/EW110N9K4

R900556472 4WE6Y62/EG24K4QMAG24

R900561276 4WE6Y62/EG24N9K4

R900909178 4WE6Y62/EG24N9K4/B08

R900917497 4WE6Y62/EG24N9K4/B10

R900922335 4WE6Y62/EG220N9K4

R900765505 4WE6Y62/EG26N2K4K

R901073870 3WE6A62/OFEG220N9K4

R901235381 4WE6D46-62/OFEG24N9K72LSO407

R900561274 4WE6D6X/EG24N9K4

R900574632 4WE6D62/EG24K4QMBG24

R900909559 4WE6D6X/EW230N9K4

R900546257 4WE6D73-62/EG24N9K4/A12

R901235374 4WE6D73-6X/EG24N9K72L/A12

R900927437 4WE6D73-62/EG24N9K4/A12B10

R900561278 4WE6E62/EG24N9K4

R900903464 4WE6E62/EG24N9K4/V

R900921477 4WE6E62/EG24N9K4/B10

R900558641 4WE6E62/EW110N9K4

R900912492 4WE6E62/EW230N9K4

R901259406 4WE6E73-62/EG24N9K72L/A12=AN

R900561280 4WE6EA62/EG24N9K4

R901162080 4WE6EB62/EG220N9K4

R901034409 4WE6E6X/BG24NXDZ2/V

R900551703 4WE6J62/EW110N9K4

R900908878 4WE6J62/EG110N9K4

R900561288 4WE6J62/EG24N9K4

R900901045 4WE6J62/EG24N9K4/B08

R900548271 4WE6J62/EG24N9K4/B10

R900922535 4WE6J62/EG24N9K4/B20

R900911762 4WE6J62/EW230N9K4

R900912079 4WE6J62/EW230N9K4/B10

R900548772 4WE6J62/EG24N9K4/V

R900922207 4WE6J62/EG220N9K4

R901235012 4WE6J62/EG24N9K72L

R900548271 4WE6J6X/EG24N9K4/B10

R900765511 4WE6J62/EG26N2K4K

R900561291 4WE6JB62/EG24N9K4

R900932917 4WE6JB62/EG24N9K4/V

R900561292 4WE6Q6X/EG24N9K4

R901235370 4WE6Q62/EG24N9K72L

R900940418 4WE6Y11-62/EG24N9K4

R900561286 4WE6H62/EG24N9K4

R900549534 4WE6HA62/EG24N9K4

R900561282 4WE6G62/EG24N9K4

R900912493 4WE6G62/EW230N9K4

R900561284 4WE6GA62/EG24N9K4

R900549534 4WE6HA62/EG24N9K4

R900578186 4WE6UA62/EG24N9K4

R901396248 4WE6U62/EG220N9K4/V

R901509281 4SEC6E2X/G24N9K4

REXROTH plug-in connector 3P Z5L M 12-240V SPEZ

R901017022

Mating connector, 3-pin (2 + PE) EN 175301-803, with LED, black

For valves with plug K4. OEM accessories. Industrial use.

Power supply voltage 12… 240 V AC/DC

Electrical plug 3 pin device plug (2 + PE)

Electrical connection description 3-pin device connector (2 + PE) according to EN 175301-803

Weight [kg] 0.038

Rexroth REXROTH Direct acting directional slide valve with electromagnetic activation

WE 6... H

strength 6

Component Series 7X

High working pressure 315 bar

High flow 60 l/min

Three-position four-way, two-position four-way or two-position three-way model

standard models

Port mounting surface acc. to DIN 24340, Form A

DC coil with wet pins

Electromagnetic coil rotatable

When replacing the coil, there is no need to open the pressure-resistant sealed cavity

Electrical connections as single connections

implicit manual emergency operation

The directional valve for WE models is a solenoid operated directional spool valve. These valves control the start, stop and direction of the fluid.

These directional valves consist essentially of a housing, one or two coils, a control spool and one or two return springs. In case of power failure, the control spool is fixed in the center position or initial position by the return spring. The control spool is actuated by a coil with wet pins.

To ensure proper operation, make sure that the pressure chamber of the coil is filled with hydraulic oil!

The force of the coil acts on the control spool via the push rod and pushes the latter from its rest position to the desired end position. This frees up the desired flow direction depending on the symbol. After the coil is demagnetized, the return spring pushes the control spool back to its rest position.

Manual emergency operation controls the spool when the coil is not energized.

German Rexroth REXROTH solenoid valve Order No. and model:

R901089245 4WE6C70/HG24N9K4

R901087088 4WE6D70/HG24N9K4

R901087087 4WE6E70/HG24N9K4

R901108990 4WE6J70/HG24N9K4/B10

R901133322 4WE6HA70/HG24N9K4

R901089241 4WE6J70/HG24N9K4

R901108990 4WE6J70/HG24N9K4/B10

R901108705 4WE6JB70/HG24N9K4

Rexroth REXROTH Direct acting directional slide valve with electromagnetic activation

WE 10... E

size 10

Component Series 5X

High working pressure 350 bar

High flow rate 160 l/min

Three-position four-way, two-position four-way or two-position three-way model

Oil port mounting surface according to ISO 4401-05-04-0-05

High power coil, optional rotation 90°

Electrical connections as single or centered connections

Optional use with PWM connector (fast switching amplifier, energy saving)

Auxiliary controls, optional

CE>> compliance with Low Voltage Directive 2014/35/EU at 50 VAC or 75 VDC

Solenoid coil is approved component with UR marking, optional

CSA C22.2 139-13 certified, optional

The directional valve for WE models is a solenoid operated directional spool valve that can be used as a solenoid assembly. The valve controls the start, stop and direction of the fluid.

The directional valve basically consists of a housing, one or two electromagnets, a control spool and a return spring. In the de-energized state, the control spool is held in the neutral or initial position by the return spring (except version O). When the electromagnet in the hydraulic oil is switched on, the control spool is moved from its rest position to the desired end position. This signals the desired flow direction based on the selected symbol.

When the solenoid is switched off, the control spool is pushed back to the neutral or initial position (except valves with OF and valves without spring type O

Auxiliary operation allows manual switching of the valve without energizing the magnet.

The hydraulic system must be properly ventilated to ensure proper functioning.

Without spring return" O" (only applicable to symbols A, C and D)

This model is a directional valve with two switching positions and two electromagnets without actuator. Valves without spring return at the control spool have no defined initial position in the de-energized state.

Without spring return, with device" OF" (symbols A, C and D only)

This model is a directional valve with two switch positions and two electromagnets with actuators. The control valve core is fixed in the corresponding switching position through the device. Therefore, no current needs to be applied to the electromagnet during operation, which contributes to energy-saving operation.

Model 73... A12" (soft handoff behavior)

The combination of control spool and solenoid reduces the number of reversing strokes that occur when the valve opens or closes.

The reversing stroke (measured as acceleration value a) can be reduced by approximately 85% compared to standard valves, depending on the type of control spool (see acceleration value).

Note:

Pressure spikes in drain lines connecting two or more valves may cause unintended control spool movement on models with actuators. It is recommended to lay a separate return line or install a check valve in the drain line.

Due to the design principle, internal leakage occurs in the valve, and the leakage volume increases during the service life.

throttle insert

Depending on the prevailing operating conditions, throttle inserts will be required if flow exceeding the performance limits of the valve is likely to occur during switching.

German Rexroth REXROTH solenoid directional valve Order No. and model:

R900944371 4WE10D33/CG220N9K4/V

R901487117 4WE10C50/EW230N9K4/M

R900598925 4WE10D33/CW110N9K4

R900912496 4WE10D33/CW230N9K4

R900923393 4WE10D33/CW230N9K4/V

R901336181 4WE10D50/EG205N9K4/M

R901344560 4WE10D50/EG220N9K4/V

R901339383 4WE10D50/EG220N9K4/M

R901278760 4WE10D50/EG24N9K4/M

R901483529 4WE10D50/EW230N9K4/M

R901391200 4WE10D50/HG24N9K4/M

R901344562 4WE10D50/OFEG220N9K4/M

R901278763 4WE10D50/OFEG24N9K4/M

R901278761 4WE10E50/EG24N9K4/M

R901390857 4WE10E50/HG24N9K4/M

R900595532 4WE10EA33/CG24N9K4

R901278780 4WE10EB50/EG24N9K4/M

R901278768 4WE10G50/EG24N9K4/M

R901427832 4WE10G50/HG24N9K4/M

R900597986 4WE10H33/CG24N9K4

R901349517 4WE10HB50/EG24N9K4/M

R900593805 4WE10J33/CW230N9K4

R901278744 4WE10J50/EG24N9K4/M

R901401552 4WE10J50/HG24N9K4/M

R901327207 4WE10J50/EG205N9K4/M

R901278782 4WE10JA50/EG24N9K4/M

R901278784 4WE10R50/EG24N9K4/M

R901349519 4WE10RB50/EG24N9K4/M

R901333735 4WE10T50/EG24N9K4/M

R901391202 4WE10Y50/HG24N9K4/M

R900591664 4WE10D3X/OFCG24N9K4

R901391203 4WE10C51/HG24N9K4/M

R901391200 4WE10D51/HG24N9K4/M

R901390857 4WE10E51/HG24N9K4/M

R901427832 4WE10G51/HG24N9K4/M

R901427828 4WE10H51/HG24N9K4/M

R901427828 4WE10H52/HG24N9K4/M

R901401552 4WE10J51/HG24N9K4/M

R901391161 4WE10L50/HG24N9K4/M

R901278778 4WE10U50/EG24N9K4/M

Rexroth REXROTH Direct acting directional slide valve with electromagnetic activation

Z4WE 6

strength 6

Component Series 3X

High working pressure 315 bar

High flow rate 50 l/min

weight

Single coil 1.2kg

Double coil 1.6kg

Temperature range -20… +50℃

characteristic

Two-position four-way and three-position four-way directional stop valves

sandwich plate valve

As a straight or short circuit valve

Oil port mounting surface according to ISO 4401-03-02-0-05 (with or without holes)

AC or DC electromagnets switched in oil

Optional use with PWM connector (fast switching amplifier, energy saving)

Auxiliary controls, optional

Spool position monitoring, optional

CE>> compliance with Low Voltage Directive 2014/35/EU at 50 VAC or 75 VDC

Z4WE directional valve is solenoid operated directional spool valve. The valve controls the start, stop and direction of the fluid.

The directional valve basically consists of a housing, one or two coils, a control spool and two return springs.

In the non-operating state, the control spool is held in the center position or initial position by a return spring. Control spool is operated by wet pin coil.

The hydraulic system must be properly ventilated to ensure proper functioning.

The force of the coil acts on the control spool via the plunger and pushes it from the rest position to the desired end position. This releases the required flows A② to A① and B② to B①.

After the coil is de-energized, the control spool is pushed back to the rest position by the return spring.

Optional manual emergency operation moves the control spool without energizing the coil.

Note:

Due to the design principle, the valve will inevitably have internal leakage, and the leakage will increase with the increase of service time.

Permissible shock and vibration loads are described in parameter sheet 08012.

Note:

The solenoid valve generates voltage spikes during closing. In order to prevent electromagnetic interference in the system and damage to the valve control, interference protection circuits must be provided on the system side. Alternatively, connectors with integrated interference protection circuits can be selected.

Note:

When establishing electrical connections, the protective earth conductor (PE ) must be connected correctly.

It must be routed in a way that reduces tension!

Cable bundle coils are only suitable for installed cables.

During operation, the connector shall be locked. During normal operation with loads, it must not be plugged in or disconnected.

Protective earth conductor cross section equal to or greater than line cross section of power supply.

The valve mounting face must be connected to the protective earth conductor system.

German Rexroth REXROTH solenoid valve Order No. and model:

R901087024 Z4WE6X252-31/EG24N9K4/V/60

R900936096 Z4WE6E68-3X/EG24N9K4/V

R900941535 Z4WE6E68-3X/EG24K4/V

Rexroth pilot operated pressure relief valve R900917775 3DR16P5-53/250Y/00M- Name(chinese)

- Name(English)

- Shanghai Weimi Mechanical and Electrical Equipment Co., Ltd.

- China credit code

- Identity Verification

- Product Category

- Bosch REXROTH Hydraulic ComponentsAVENTICS Pneumatic Components

- Address

-

Shanghai Pudong New District, China

- Nearby port

- Shanghai

Shanghai Weimi Electromechanical Equipment Co., Ltd. is located in Jinqiao Yuzhou International, Pudong New District, Shanghai City. It is a trading company engaged in the management of foreign imported hydraulic and pneumatic spare parts and automated instruments; focusing on the field of industrial transmission automation fluids in China. The company adheres to the concept of integrity and service-oriented. Resolutely safeguard the interests of customers, protect the original products of our brands, provide customers with preferential prices, high-quality products and after-sales sales, achieve win-win cooperation, and create a good trade partnership. Our main products are solenoid valves, proportional valves, plunger pumps, pressure relays, pressure sensors, servo drivers, servo motors, programmable controllers, PLC modules, I/O modules, sensors, cylinders, pneumatic valves, compressed air processing units, industrial instruments, etc. The operating brands include: Bosch Rexroth, AVENTICS, Atos ATOS, Dipma DuploMATIC, B&R, Bentley Bently, Airtec Airtec, Seg ASCO, MooG, PARKER Parker, EATON VICKERS Eaton Vickers, Siemens and other imported brands. We sincerely welcome friends from all walks of life to call us for consultation, on-site inspection and business negotiation.- Name(chinese)

- Name(English)

- Shanghai Weimi Mechanical and Electrical Equipment Co., Ltd.

- China credit code

- Identity Verification

- Product Category

- Bosch REXROTH Hydraulic ComponentsAVENTICS Pneumatic Components

- Address

-

Shanghai Pudong New District, China

- Nearby port

- Shanghai

Shanghai Weimi Electromechanical Equipment Co., Ltd. is located in Jinqiao Yuzhou International, Pudong New District, Shanghai City. It is a trading company engaged in the management of foreign imported hydraulic and pneumatic spare parts and automated instruments; focusing on the field of industrial transmission automation fluids in China. The company adheres to the concept of integrity and service-oriented. Resolutely safeguard the interests of customers, protect the original products of our brands, provide customers with preferential prices, high-quality products and after-sales sales, achieve win-win cooperation, and create a good trade partnership. Our main products are solenoid valves, proportional valves, plunger pumps, pressure relays, pressure sensors, servo drivers, servo motors, programmable controllers, PLC modules, I/O modules, sensors, cylinders, pneumatic valves, compressed air processing units, industrial instruments, etc. The operating brands include: Bosch Rexroth, AVENTICS, Atos ATOS, Dipma DuploMATIC, B&R, Bentley Bently, Airtec Airtec, Seg ASCO, MooG, PARKER Parker, EATON VICKERS Eaton Vickers, Siemens and other imported brands. We sincerely welcome friends from all walks of life to call us for consultation, on-site inspection and business negotiation. -

Send your message to this supplier*From:*To:

Mr. Lei Qing

*Message:

Mr. Lei Qing

*Message:Inquiry

Copyright © 2003 - 2025 Goepe.com All rights reserved.