-

Product DescriptionCompany Info.<>

- Model:

- R900722870

- Processing customization:

- No

- Material:

- cast steel

- Applicable medium:

- hydraulic oil

- Nominal pressure:

- 350bar

- Nominal diameter:

- 6

- Valve connection mode:

- threaded

- Overall dimension:

- 50 mm

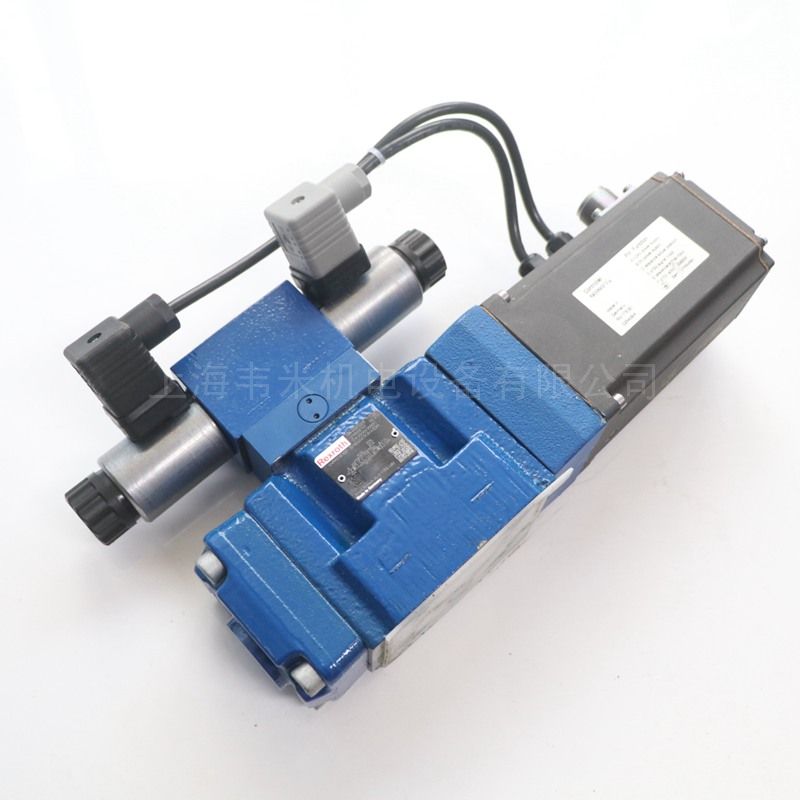

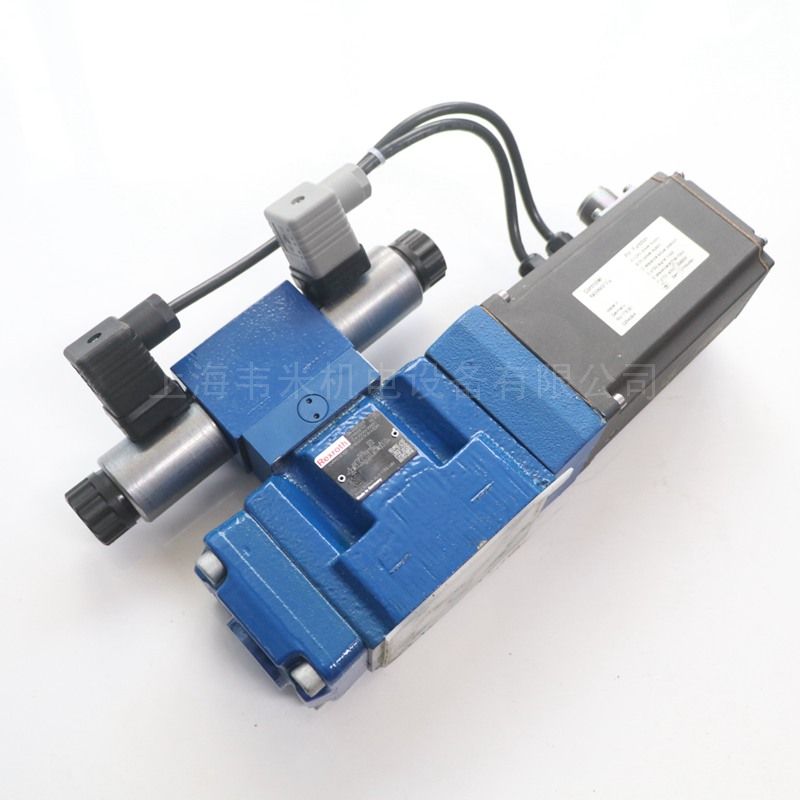

Rexroth proportional valve 4WRKE10E100P-35/6EG24ETK31/A1D3M, Shanghai Weimi Electromechanical Equipment Co., Ltd. Main products, real photos, original, affordable; warmly welcome new and old customers to consult and buy!

Rexroth REXROTH proportional valve R900722870

Hydraulic proportional directional valve 4WRKE10E100P-3X/6EG24ETK31/A1D3M

R900722870 4WRKE10E100P-35/6EG24ETK31/A1D3M

Nominal size 10, symbol E, electrical control via integrated electronics

Industrial hydraulic valves in the high performance range, reliable control of oil flow direction according to hydraulic symbols, high accuracy through internal piston position feedback

slide valve

servo-motor controlled

Internal pilot supply, internal pilot return

Characteristic curve linearity with fine control range

product attribute

Connection diagram ISO 4401-05-05-05

Product Series 4WRKE

Operating pressure [bar] 315

Flow rate [l/min] 170

Slide valve symbol Symbol E

Connection Type Base Plate Installation

Nominal flow [l/min] 100

size 10

Drive type Electrical with on-board electronics

Number of ports 4.

Number of switching positions 3.

Supply voltage 24 VDC

Electronic connector connector, 7 pole (6+PE)

Electrical connection description Connector 7 poles (6+PE) according to EN 175201-804

Wireless connection analog, command value± 10 V

Hydraulic fluids HL, HLP, HLPD, HVLP, HVLPD, HFC

Seal NBR

Weight [kg] 8.36

Rexroth REXROTH Pilot Proportional Directional Cartridge Valve

R901388132 2WFCE50S1000L-1X/M/24A1

throttle control

Sizes 50, A→ B, B→ A, Integrated electronics, 24 V DC

Industrial hydraulic valves in the high performance range. Reliable flow restriction with high response behavior to command values on selected ports. High accuracy due to internal piston position feedback.

slide valve

pilot operation

linear flow characteristics

product attribute

Connection diagram ISO 7368-BE-11-2-A

Product Series 2WFC (E)

Operating pressure [bar] 420

Spool symbol A– B, B– A

Connection type Cartridge valve

Nominal flow [l/min] 1000

size 50

Drive Type Integrated electronics Electrical

Number of ports 2.

Number of switching positions 2.

Supply voltage 24 VDC

Electrical Connector Connector, 7 Pole (6+PE)

Electrical connection description Connector 7 poles (6+PE) according to EN 175201-804

Connectivity analog, command value 0… 10 V

Statement of Conformity CE– Electromagnetic Compatibility 2014/30/EU RoHS Directive 2011/65/EU REACH Regulation (EC) No 1907/2006

Hydraulic fluids HL, HLP, HLPD, HVLP, HVLPD, HFC

Seal NBR

Weight [kg] 10

Rexroth REXROTH proportional throttle valve

R901451944 2WFC32S320L-1X/M/K4

Size 32, A→ B, B→ A, External Amplifier, 24 V DC

Industrial hydraulic valves in the high performance range. Reliable flow restriction with high response behavior to command values on selected ports. High accuracy due to external piston position feedback.

slide valve

pilot operation

linear flow characteristics

product attribute

Connection diagram ISO 7368-BC-09-2-A

Product Series 2WFC (E)

Operating pressure [bar] 420

Spool symbol A– B, B– A

Connection type Cartridge valve

Nominal flow [l/min] 320

size 32

Drive type Electrical with external electronics

Number of ports 2.

Number of switching positions 2.

Supply voltage 24 VDC

Electrical connector 3 pole connector (2+PE)

Electrical connection description 3-pole connector (2+PE) according to EN 175301-803

Hydraulic fluids HL, HLP, HLPD, HVLP, HVLPD, HFC

Seal NBR

Weight [kg] 4.54

Rexroth REXROTH Pilot Proportional Directional Cartridge Valve

FES

Specifications 25, 32, 40, 50, 63

Component Series 3X

High working pressure 315 bar

Temperature range -20… +80℃

High working pressure 315bar

Viscosity range 15… 380mm²/s

Lag < 0.2%

Response sensitivity < 0.1%

Reverse deadband < 0.15%

Voltage Type DC Voltage

Rated current 1000mA

Intuition 6... 8mH

Oscillator frequency 2.5kHz

Differential throttle of electrical position measuring system

Pilot two-way proportional throttle valve in oil circuit block installation technology

Mounting size according to DIN ISO 7368

Throttle spool electric position control

bidirectional circulation

If there is a power failure or cable interruption, the throttle spool will automatically enter the seated position and prevent bidirectional flow

Together with a pressure balancing valve, it can be used for pressure compensated flow control.

For external analog electronics

Type FES valves are pilot-operated, two-way proportional throttle valves for block mounting to provide continuous flow control.

Technical settings:

The valve consists of four main assemblies:

Cap with connection face for pilot oil connection

Main valve with throttle spool

Pilot control valve with proportional solenoid

Control of the position of the throttle spool in relation to the control value and the orifice opening defined thereby.

The flow depends on p between the orifice and the position of the throttle spool.

The theoretical value of the throttle spool position is recorded using a position sensor; the control/theoretical value is compared in the electronics; the difference is prepared and used as a control output to correct the position of the throttle spool relative to the proportional solenoid and pilot control valve.

The area ratio of regions to regions of NG25, 32, and 40 specifications is 2 : 1, and the area ratio of regions to regions of NG50 and 63 specifications is 1.6 : 1.

Flow direction A→ B (connect X to A);

Flow direction B→ A (connect X to B);

External pilot oil that may be supplied through X.

When disconnect is enabled, the throttle spool moves to the seated position and blocks flow to A B in a leak-free manner. The spool seal seals port B to the control chamber in a leak-tight manner; for internal pilot oil supply, note oil leakage from X to Y through the pilot control valve!

The throttle spool position with a control value of 0 V or 4 mA has been adjusted while the orifice is still in the positive overlap position.

The proportional solenoid moves the pilot spool against the spring and opens the connection from the control chamber to Y; under the combined effect of the pressure in area A and the pressure in annular area B, the control chamber is depressurized and the throttle spool moves in the opening direction.

Flow decreases at proportional solenoid; spring moves pilot spool away from proportional solenoid and opens connection from X to control chamber; pressure increases in control chamber; pressure at area and spring force combine to move throttle spool in closing direction

Can be used with pressure compensator to provide pressure compensated flow control

Integrated electronics stop supplying power to the coil in case of a power supply voltage failure or cable interruption of the position sensor

The pressure at control port X and the spring force work together to move the spool to the seated position and block the flow of A B.

General function:

Open throttle spool function:

(Assuming flow A→ B and A connected to X)

Close throttle spool function:

(Assuming flow A→ B and A connected to X)

Flow control function:

Power supply voltage fault:

Attention;

A failure of the supply voltage will cause the control shaft to suddenly stop. The acceleration forces generated in this connection may cause mechanical damage!

Rexroth REXROTH three way model direct acting proportional pressure reducing valve

3DREP(E) 6

strength 6

Component Series 2X

Installation position arbitrary position, preferably horizontal

Weight 2kg

Temperature range -20… +80℃

Recommended Viscosity Range 30… 46

Lag ≤ 5%

Repeatability ≤ 1%

Response sensitivity ≤ 0.5%

Reverse Dead Zone ≤ 1%

High working pressure 100 bar

High flow rate 15 l/min

Voltage Type DC Voltage

Signal Type Analog

Direct acting proportional valve for controlling pressure and flow direction

Manipulation via proportional electromagnet with central thread and detachable coil

For base plate mounting: hole diagram according to ISO 4401

Manual emergency operation, optional

spring-centered control slide

Model 3DREPE with integrated electronics (OBE)

Model 3DREP with external electronics

Three-way pressure relief valve type 3 DREP 6.. Direct motion operation by proportional electromagnet. It converts electrical input signals into proportional pressure output signals. Proportional electromagnets are controllable wet pin DC coils with centering threads and detachable coils. These coils can be selectively controlled by external control electronics (type 3DREP) or integrated control electronics (type 3DREPE).

Settings:

The basic components of the valve include:

Shell with connecting surface

Control spool with pressure measuring spool

coil with centering thread

Optional integrated control electronics

Function:

Set the pressure in A or B by proportional electromagnet. The amount of pressure depends on the current. When the coil is de-energized, the control spool is held in the center position by a compression spring. Ports A and B are connected to T so that hydraulic oil can flow unimpeded into the tank. By energizing the proportional solenoid (e.g. coil a), the pressure measuring spool and the control spool will move to the right. This will open the connections from P to B and from A to T by throttling cross-sections with progressive fluid characteristics. The pressure built up in passage B acts on the control spool through the surface of the pressure measuring spool, resisting the magnetic force of the coil. The pressure measuring spool is supported by coil b. If the pressure exceeds the value set on coil a, push the control spool back against the coil magnetic force and establish the connection between B and T until the set pressure is reached again.

Pressure is proportional to coil current. When the coil is closed, the control spool returns to the center position under the action of the compression spring. Optional manual emergency operating element moves the control spool without energizing the coil.

Note:

Accidental activation of manual emergency operating elements may result in uncontrolled machine movements!

Valves with two spool positions (Model 3DREP.. A.. or 3DREP.. B..):

Basically, the function of this valve corresponds to that of a valve with three spool positions. However, dual spool position valves are only equipped with coil a or coil b. It is fitted with a protective plug instead of a second proportional electromagnet.

Note:

Do not allow tank lines to run empty. A preload valve (preload pressure approx. 2 bar) must be installed under the appropriate installation conditions.

Control value:

Reference potential at E and positive control value at D (or 12... 20 mA) causes pressure at A.

Reference potential at E and negative control value at D (or 12... 4 mA) causes pressure at B.

Through the valve with coil on side b(type A), reference potential at E and positive control value at D (4... 20 mA) will cause pressure at A.

Through a valve with coil on side a(type B), reference potential at E and positive control value at D (4... 20 mA) will cause pressure at B.

Connecting cables:

Recommended:

Cable length not exceeding 25 m: Type LiYCY 5 x 0.75 mm2

Cable length not exceeding 50 m: Type LiYCY 5 x 1.0 mm2

Outer diameter 6.5 to 11 mm

Connect shield to PE on supply side.

German Rexroth REXROTH Proportional Pressure Reducing Valve Order Numbers and Models:

R900956101 3DREP6C-20=25EG24N9K4/M=00

R900956101 3DREP6C-21=25EG24N9K4/M=00

R900958788 3DREPE6C-21=25EG24N9K31/A1M=00

R901280845 3DREE10P-7X/200YG24K31F1V

REXROTH proportional pressure control valve Z3DREE10VP2-1X/100XLG24K31A1M

R901483244 Z3DREE10VP2-10/100XLG24K31A1M

Nominal size 10, P2P1→, electrical with integrated electronics, 24 V DC

Industrial hydraulic valves in the high performance range. Signal to reliably reduce pressure to set point.

slide valve

pilot

Pressure class 100 bar

analog electronic component

High pressure [bar] 350

High volume flow [l/min] 120

Piston symbol P2→ P1

Connection Type Overlay Valve Plate

Nominal size 10

Drive Type Electrical Belt Integrated Electronics

Number of connections 4

Number of switch positions 3

Supply voltage 24 VDC

Electrical plug 7 pin device plug (6 + PE)

Electrical connection instructions 7-pin device plug (6 + PE) according to EN 175201-804

Connect analog, setpoint 0… 10 V

Statement of conformity CE -Electromagnetic compatibility 2014/30 / EU

Hydraulic fluids HL,HLP,HLPD,HVLP,HVLPD,HFC

Seal NBR

Weight [kg] 3.4

REXROTH proportional pressure control valve Z3DREE10VP2-1X/200XLG24K31A1M

R901483246 Z3DREE10VP2-10/200XLG24K31A1M

Nominal size 10, P2P1→, electrical with integrated electronics, 24 V DC

Industrial hydraulic valves in the high performance range. Signal to reliably reduce pressure to set point.

slide valve

pilot-operated

Pressure rating 200 bar

analog electronic component

Pressure [bar] 350

Piston symbol P2→ P1

Connection Type Overlay Valve Plate

Nominal size 10

Drive Type Electrical Belt Integrated Electronics

Number of connections 4

Number of switch positions 3

Supply voltage 24 VDC

Electrical plug 7 pin device plug (6 + PE)

Electrical connection instructions 7-pin device plug (6 + PE) according to EN 175201-804

Connect analog, setpoint 0… 10 V

Statement of conformity CE -Electromagnetic compatibility 2014/30 / EU

Hydraulic fluids HL,HLP,HLPD,HVLP,HVLPD,HFC

Seal NBR

Weight [kg] 3.4

REXROTH Direct acting proportional relief valve with position feedback (Lvdt AC/AC)

0811402001 DBETBX-10/250G24-37Z4M-38

0811402003 DBETBX-10/180G24-37Z4M

0811402004 DBETBX-10/315G24-37Z4M

DBETBX

strength 6

Component Series 1X

High working pressure 315 bar

Rated flow 1 l/min

Direct-acting valve with position feedback to limit system pressure

Position control with strong coil magnetic force

High pressure limit (even with faulty electronics)

For base plate mounting: hole diagram according to ISO 4401

Proportional relief valve type DBETBX is a remote control valve (pilot control valve) with cone valve structure, which can be used to limit system pressure infinitely. They are actuated by position-controlled proportional electromagnets.

01 Direct acting proportional relief valve with position feedback (Lvdt AC/AC)

DBETB

02 Oil port mounting surface conforms to ISO 4401-03-02-0-05

X

03 Component series 10... 19(10 ... 19: Installation and connection (size unchanged)-Specification 10

1X

high pressure rating

04 High 28 bar

28

High 80 bar

80

High 180 bar

180

High 250 bar

250

High at 315 bar

315

power supply

05 DC voltage 24 V

G24

Coil model (current)

06 Large coil current 3.7 A

37

electrical connection

07 Connector acc. to DIN 43650-AM2 Connection plug included in scope of delivery

Z4

sealing material

08 NBR seal

M

Rexroth REXROTH Pilot Proportional Relief Valve

Model DBE6X

Size NG 6

Equipment Series 1X

Working principle P=315bar, T=250bar

Flow rate 40l/min

characteristic

- Pilot valve for limiting system pressure (control oil only internally)

- Adjustable via coil current, see characteristic curves, technical data and selected electronic control unit

- electromagnet type Imax=0,8A or 1max=2,5A

- High degree of overvoltage protection (coil current 1 max) even when the electronic control unit is damaged>'

- For valve plate mounting, mounting holes conform to ISO 4401-03-02-O-94, mounting to be ordered separately

- Cable socket according to DIN 4365O-AM2, incl.– external electronic control unit with ramp function and valve regulation within scope of supply (ordered separately),

Model/structure type is as follows

Plug, rating 0...+ 10V or 4... 20 mA, RC 30264

Module, rated O...+ 10 V,RC 30222

European standard card, rated O...+ 10 V, RC 30109

summarize

Proportional relief valve DBE6X is a pilot operated relief valve.

The inner pilot stage of the cone-seat type and the main stage of the spool type are both in the valve body.

Control by proportional electromagnet. The electromagnet is damped by a throttle valve in the armature to ensure dynamic stability. The inner cavity of the electromagnet is connected with the interface I and filled with hydraulic oil.

Venting can be done via screw plugs.

These valves allow the system pressure to be limited to be adjusted in a stepless manner according to coil current variations.

fundamental

The system pressure is regulated by determining a setpoint value via the electronic control unit. The electronic control unit uses the regulated PWM current according to the set value

(PWM pulse width modulation) controls the coil coils. Oscillating signals are used to modulate the regulated current to ensure minimal hysteresis.

Proportional electromagnets convert the current into mechanical force and act on the main spring in the pilot stage via armature tappets. Control oil at a flow rate of 0,6 l/min is supplied to the pilot stage via the oil supply bore.

Pressure levels are determined by taper/socket configurations.

Degree of overvoltage protection available: pmax.

If a fault occurs in the electronic control unit and the coil current (1max) is exceeded as a result of the runaway, overvoltage protection is ensured by the spring force.

general parameters

structural style

pilot stage seat valve

main-stage slide valve

Control proportional electromagnets without position adjustment, external electrical amplifiers

Mounting method Plate connection, NG6 mounting holes (ISO 4401-03-02-0-94)

Installation position arbitrary

Ambient temperature range-20...+ 50℃

Weight 2,2kg

Vibration strength, test condition 25g, three-dimensional random vibration test (24 hours)

Hydraulic parameters (measured using HLP46,ü oil =40° ℃ ± 5° ℃)

Hydraulic oil according to DIN 51524... 535 standard hydraulic oil, other media can be used according to needs

viscosity range

Recommended value 20... 100mm²ls

Allowable values 10... 800mm²/s

Hydraulic oil temperature range-20...+ 80℃

Permissible degree of contamination of hydraulic oil Cleanliness class according to ISO 4406 (c) class 18/16/13) The cleanliness indicated for the relevant component must be strictly observed in hydraulic systems. Effective filtration prevents failures and increases component life. For filter selection, see catalog RD 50070, RD 50076 and RD 50081.

Regulated pressure (when o=1 l/min) 80-180-315bar

Pressure (when omin= 1 l/min) 7-8-10bar

Overvoltage protection; mechanical, e.g. when coil current I> Imax <90-< 190-< 325bar

Working pressure connection P:315bar

Pressure connection T:250bar

Control oil flow approx. 0,6l/min

Flow rate 40l/min

Electrical parameters Relative turn-on time 100 ED%

Protection class IP65 according to DIN 40050 and IEC14434/5

Solenoid connection socket DIN 43650/ISO 4400,M16x1,5 (2P+PE)

Valves with the following types of electromagnets 0,8A 2,5 A

Coil current Imax 0,8 A 2,5A

Coil resistance R20 22 3

Power consumption, when 100% load and operating temperature 25VA 30VA

Static/dynamic parameters (all characteristic parameters relate to electrical amplifier 0811 405 079 for 2,5A electromagnets and 0811405081 for 0,8A electromagnets)

Hysteresis ≤4%

Reverse Dead Zone ≤3%

Machining tolerances apply to Pmax ≤10%

Execution time 100% Signal change ON 200/OFF< 250ms

Germany Rexroth REXROTH pilot proportional relief valve:

0811402041 DBE6X-11/180G24-25NZ4M

0811402044 DBE6X-11/180G24-8NZ4M

REXROTH Direct acting proportional relief valve

0811402016 DBETX-10/315G24-8NZ4M

0811402019 DBETX-10/250G24-8NZ4M

0811402017 DBETX-10/180G24-8NZ4M

DBETX

strength 6

Component Series 1X

High working pressure 315 bar

Rated flow 1 l/min

High flow rate 1.5 l/min

floor mounting

Weight 1.9kg

Temperature range -20… +50℃

Large vibration resistance 25 g, indoor vibration test in all directions (24 h)

Recommended viscosity range 20… 100mm²/s

Lag ≤ 4%

Reverse Dead Zone ≤ 3%

Manufacturing tolerance ≤ 10%

Drive time ON 60ms OFF 70ms

Oil port mounting surface according to ISO 4401-03-02-0-05 (but without holes)

Adjustable with coil current

Coil variable Imax = 0.8 A or 2.5 A

High pressure limit (even with faulty electronics)

External control electronics with ramp and valve adjustment

general information

Proportional relief valves DBETX are remote control valves (pilot control valves) of spool-seat design. This valve is used to limit system pressure.

Operates via proportional coils.

The coil interior is connected to port T and filled with hydraulic oil.

With this valve, the system pressure to be limited can be adjusted via the control electronics according to the coil current at a flow rate of 1 l/min that is as constant as possible.

The valve is basically composed of housing, proportional coil, valve seat and valve core.

fundamental

Preset control values on the control electronics for setting the system pressure. The electronics control the solenoid coil according to the control value by means of a regulated PWM current (pulse width modulation). The proportional coil converts the current into mechanical force, which acts on the main spring through the armature plunger. A compression spring between spool and seat ensures stability and low residual pressure. The spring force on the spool and the pressure in the seat counteract at a constant oil flow (0.7 - 1 l/min). The high pressure rating is determined by the spool/seat bore configuration.

high pressure limit

Large spring forces are critical for pressure limitation in the event of failure or damage to the control electronics, resulting in uncontrolled excess coil current (Imax).

Rexroth REXROTH Pilot operated proportional pressure reducing valve with inductive position sensor

DREB6X

0811402080 DREBE6X-1X/175MG24K31A1M

0811402051 DREB6X-11/175MG24-25Z4M

strength 6

Component Series 1X

High working pressure 315 bar

Pilot flow ≈ 0.6 l/min

High flow rate 40 l/min

Installation position arbitrary

Weight 2.4kg

Ambient temperature range -20… +50℃

Hydraulic oil temperature range -20… +80℃

Viscosity range 10… 800mm²/s

Lag ≤ 1%

Manufacturing tolerance of pressure characteristic curve of control value ≤ 10%

Large coil current 2.5A

Electromagnetic coil resistance (°low temperature value at 20 C) 3Ω

Duty cycle 100%

Protection class according to DIN EN 60529 IP65

Pilot operated valve for system pressure relief, located in actuator (internal pilot oil supply only)

Three-way model

Adjustable by coil armature position relative to compression spring

Position control, small hysteresis< 1%, short drive time

High pressure limit (even with faulty electronics)

For base plate mounting: hole diagram according to ISO 4401

DREB6X proportional pressure reducing valve belongs to pilot pressure reducing valve; its main stage is three-way model. The pilot control valve (DBV pilot stage) has an internal pilot oil supply controlled by flow of P. Operation is performed by position-controlled proportional electromagnets acting on springs. Thus short drive times and small hysteresis are achieved. Pressure at A (actuator) can be set steplessly by coil current to reduce valve usage.

REXROTH pilot-operated proportional pressure reducing valve with built-in electronic control unit (OBE) and position feedback

DREBE6X

Diameter (NG)6

Equipment Series 1X

Working pressure P315 bar,T 250 bar

Volume flow rate 40 l/min

characteristic

- Pilot valve with position feedback and built-in electronic control unit for reducing system pressure on load (control oil only internally)

- Three-way type (P-A/A-T), Pmin-PT

- Adjustable by armature position relative to compression spring

- Adjustable position, small hysteresis< 1%, short execution time, see technical data

- High degree of overvoltage protection (coil current IImax) even when the electronic control unit is damaged>

- For valve plate mounting, mounting holes according to ISO 4401-03-02-O-O5, mounting plates according to catalogue RC45053(ordered separately)

- Cable socket acc. to DIN 43563-AM6, see catalogue RD o80o8(ordered separately)

- Suitable for built-in electronic control units

CE, EMV specifications EN 61000-6-2:2002-08 and EN 61000-6-3:2002-08 can meet

U=24 Vnom

Electrical connections 6P+PE

control signal

Standard 0...+ 10 V(A1)

Variant 4... 20 mA (F1)

Valve characteristic curve calibrated at factory

summarize

DREBE6X proportional pressure reducing valve is pilot type, the main stage is three-way structure. Control oil with regulated flow is supplied to the pilot valve (DBV-pilot stage) via Р.

Control via position-adjustable proportional electromagnet with built-in electronic control unit. With these valves, the pressure in A(load) can be continuously adjusted and reduced according to the set value.

fundamental

The system pressure in A is regulated by determining a setpoint value via the electronic control unit. The electronic control unit controls the position of the electromagnet against the spring force according to the set value. Proportional electromagnets are accurately positioned according to spring characteristic curves. Hydraulic oil with a flow rate of less than 0.6 l/min is supplied to the pilot stage via the flow regulating valve from Р.

Compare and adjust the pilot pressure to the load pressure (applied spring force) in A. The spring makes PAmin=P in T.

Provides a high degree of overvoltage protection

If a fault occurs in the electronic control unit and the coil current (1ax) is exceeded as a result of the runaway, overvoltage protection is achieved primarily by spring force.

general parameters

structural style

pilot stage seat valve

main-stage slide valve

Control of proportional solenoid valves with position adjustment, OBE

Mounting method Plate connection, NG6 mounting hole (ISO 4401-03-02-0-05)

Installation position arbitrary

Ambient temperature range-20...+ 50℃

Weight 3.3kg

Vibration strength, test condition 25g, three-dimensional random vibration test (24 hours)

Hydraulic parameters (measured values using HLP46, oil =40° C ± 5° C)

Hydraulic oil according to DIN 51524... 535 standard hydraulic oil, other media can be used according to needs

viscosity range

Recommended value 20... 100mm²/s

Allowable values 10... 800mm²/s

Hydraulic oil temperature range-20...+ 70℃

Permissible contamination of hydraulic oil Cleanliness class according to ISO 4406 (c) Class 18/16/13 1

Regulation pressure in A (when Qmin= 1 Vmin 75 175 310bar

Small pressure 0(relative) in A or pressure bar in T

Small inlet pressure in Р bar pp=PA+=

Working pressure connection P:315bar

Pressure connection T:250bar(B closed)

Control oil flow 0,6l/min approx.(adjustable)

Flow rate 40l/min

Static/Dynamic Parameters Hysteresis ≤ 1% Regulation Pressure

Machining tolerance ≤ ± 5% Adjustment pressure

execution time

100% signal change 50ms

10% Signal Change 20ms

Temperature fluctuation < 1% at AT= 40℃

Electrical parameters, electronic control unit integrated in valve

Relative Endurance Rate 100% ED

Protection class lP65 according to DIN 40050 and IEC14434/5

Connection cable socket 6P+PE,DIN 43563

Power supply voltage 24 V-nom

Terminal A: 21 V=/40 V=

Terminal B:0V Waviness 2V=

Power dissipation electromagnet 45 mm =40 VA

External fuses 2,5 AF

Input,“ standard" A1 differential amplifier, R =100 kS

Terminal D : Ue 0...+ 10 v

Terminal E: 0V

Input, Type“ mA Signal” F1 Load,Rh=200Q

Terminal D:ID-E 4... 20 mA

Terminal E:lD-E Current loop Id-e Feedback

Differential input voltage D→ B E→ B 18V corresponding to 0V

Test signal, type“ standard” A1 LVDT

Terminal F:UTest 0...+ 10 V

Terminal C: Reference voltage 0V

Input, type mA signal F1 External load 200... LVDT signal on 50o 4... 20 mA

Terminal F: IF-c 4... 20 mA output

Terminal C: lF-c current loop lf-c feedback

Recommended cables See plug pin configuration Less than 20 m 7 x0,75 mm; Less than 40 m 7 x 1 mm

German Rexroth REXROTH Proportional Pressure Reducing Valve Order Numbers and Models:

0811402082 DREBE6X-11/75MG24K31A1M

Rexroth REXROTH Direct acting proportional relief valve with integrated electronics (OBE) and position feedback

DBETBEX

strength 6

Component Series 1X

High working pressure 315 bar

Rated flow 1 l/min

Weight 2.7kg

Installation position arbitrary

Ambient temperature range -20… +50℃

Duty cycle 100%

Protection class according to DIN EN 60529 IP65

power supply 24V

Power supply voltage range 40… 21V

Hydraulic oil temperature range -20… +70℃

Lag ≤ 0.2%

Reverse deadband ≤ 0.1%

Direct-acting valve with integrated electronics and position feedback to limit system pressure

Adjustable by coil armature position relative to compression spring

Position control, small hysteresis< 0.2%, short drive time

High pressure limit (even with faulty electronics)

For base plate mounting: hole diagram according to ISO 4401

Proportional relief valve type DBETBEX is a remote control valve (pilot control valve) with cone valve construction that can be used to limit system pressure. They are actuated by position-controlled proportional electromagnets. This valve features short actuation times and low hysteresis.

German Rexroth REXROTH Proportional Relief Valve Order No. and Model:

0811402070 DBETBEX-10/315G24K31A1M

0811402073 DBETBEX-10/250G24K31A1M

Rexroth REXROTH Pilot Proportional Relief Valve

R901363276 DBEM10-71/350YG24K4V

DBEM

Component Series 7X

High working pressure 350 bar

Pilot operated valve for limiting system pressure

Controlled by proportional electromagnets

For base plate mounting and threaded connections: Port mounting surface according to ISO 6264

high pressure limit

Valve and control electronics are from the same family

External control electronics (ordered separately)

function

DBEM valve is a pilot operated relief valve. These valves are used to limit the working pressure of hydraulic systems. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The basic components of these valves include a housing with a main spool, a superposition valve with a large pressure limit, and a proportional pilot control valve.

Model DBEM...

Pressure applied in passage P acts on the main spool. At the same time, pressure at port P is applied to the spring-loaded side of the main spool through the control circuit with nozzle. Pressure is also applied to the frame of the proportional pilot control valve through the connecting bore. The hydraulic pressure at the pilot seat overcomes the proportional solenoid control value-dependent force. If the hydraulic pressure exceeds the coil magnetic force, the pilot seat opens. Pilot oil can now flow through the control circuit to port Y and to the tank; therefore, a pressure drop occurs at the main spool on the control circuit. Release the connection from port P to T. The main spool controls the set operating pressure at port P. Since hydraulic protection prevents impermissible high pressure values, spring-loaded relief valves are integrated. This high pressure limit is a preset value based on the relevant pressure level. Within the valve operating range, the spring holds the valve holder to the valve seat and the valve core closes thereby. If the pressure at the main spool spring chamber exceeds the valve's maximum allowable set point pressure, the carrier will press against the compression spring and the connection to the spring chamber will open. Pilot oil flows into the tank through port Y. Due to the presence of the control circuit, a pressure drop occurs at the main spool. Release the connection from port P to T. The main spool controls the large operating pressure set at port P. If necessary, the preset pressure can also be reduced by means of an adjusting element. Port Y must be connected from the outer tube to the tank. The tank must be connected after pressure relief. The valve can be unloaded or high pressure limited through port X.

Rexroth REXROTH Pilot operated proportional relief valve with integrated electronics (OBE)

R901344448 DBEME10-71/315YG24K31A1M

DBEME

Component series 7x

High working pressure 350 bar

Pilot operated valve for limiting system pressure

Controlled by proportional electromagnets

For base plate mounting and threaded connections: Port mounting surface according to ISO 6264

high pressure limit

Valve and control electronics are from the same family

SetPoint Manufacturing tolerances for pressure characteristic curves Integrated electronic components (OBE) with small tolerances

function

The DBEM valve is a pilot operated relief valve with integrated electronics (OBE). These valves are used to limit the working pressure of hydraulic systems. Depending on the electrical control value, these valves can be used for stepless setting of the system pressure to be limited. The basic components of these valves include a housing with a main spool, a superposition valve with a large pressure limit, and a proportional pilot control valve. The proportional electromagnet is also equipped with a housing with control electronics. Apply the supply voltage and control value voltage to the connector. The pressure characteristic curve of the control value is adjusted to very low manufacturing tolerances at the factory.

Model DBEME...

Pressure applied in passage P acts on the main spool. At the same time, pressure at port P is applied to the spring-loaded side of the main spool through the control circuit with nozzle. Pressure is also applied to the frame of the proportional pilot control valve through the connecting bore. The hydraulic pressure at the pilot seat overcomes the proportional solenoid control value-dependent force. If the hydraulic pressure exceeds the coil magnetic force, the pilot seat opens. Pilot oil can now flow through the control circuit to port Y and to the tank; therefore, a pressure drop occurs at the main spool on the control circuit. Release the connection from port P to T. The main spool controls the set operating pressure at port P.

Spring-loaded relief valves are integrated since hydraulic protection prevents abnormally high pressure values. This high pressure limit is a preset value based on the relevant pressure level. Within the valve operating range, the spring holds the valve holder to the valve seat and the valve core closes thereby.

If the pressure at the main spool spring chamber exceeds the valve's maximum allowable set point pressure, the carrier will press against the compression spring and the connection to the spring chamber will open. Pilot oil flows into the tank through port Y. Due to the presence of the control circuit, a pressure drop occurs at the main spool. Release the connection from port P to T. The main spool controls the large operating pressure set at port P. If necessary, the preset pressure can also be reduced by means of an adjusting element. Port Y must be connected from the outer tube to the tank. The tank must be connected after pressure relief. The valve can be unloaded or high pressure limited through port X.

German Rexroth REXROTH Proportional Relief Valve Order No. and Model:

R901344448 DBEME10-71/315YG24K31A1M

Rexroth REXROTH Proportional Relief Valve DBEME10-7X/315YG24K31A1M

R901344448 DBEME10-71/315YG24K31A1M

Sizes 10, P→ T, integrated electronics, 24 V DC

Industrial hydraulic valves in the high performance range. Reliable pressure relief for set signals.

pilot-operated

Continuous pressure valve with conical seat design

Pressure [bar] 350

Piston Symbol P→ T

Connection Type Sheet Structure

Nominal size 10

Drive Type Electrical Belt Integrated Electronics

Number of connections 2

Number of switch positions 2

Supply voltage 24 VDC

Electrical plug 7 pin device plug (6 + PE)

Electrical connection instructions 7-pin device plug (6 + PE) according to EN 175201-804

Connect analog, setpoint 0… 10 V

Statement of conformity CE -Electromagnetic compatibility 2014/30 / EU

Hydraulic fluids HL,HLP,HLPD,HVLP,HVLPD,HFC

Seal NBR

Weight [kg] 4.66

Rexroth proportional valve 4WRKE10E100P-35/6EG24ETK31/A1D3M- Name(chinese)

- Name(English)

- Shanghai Weimi Mechanical and Electrical Equipment Co., Ltd.

- China credit code

- Identity Verification

- Product Category

- Bosch REXROTH Hydraulic ComponentsAVENTICS Pneumatic Components

- Address

-

Shanghai Pudong New District, China

- Nearby port

- Shanghai

Shanghai Weimi Electromechanical Equipment Co., Ltd. is located in Jinqiao Yuzhou International, Pudong New District, Shanghai City. It is a trading company engaged in the management of foreign imported hydraulic and pneumatic spare parts and automated instruments; focusing on the field of industrial transmission automation fluids in China. The company adheres to the concept of integrity and service-oriented. Resolutely safeguard the interests of customers, protect the original products of our brands, provide customers with preferential prices, high-quality products and after-sales sales, achieve win-win cooperation, and create a good trade partnership. Our main products are solenoid valves, proportional valves, plunger pumps, pressure relays, pressure sensors, servo drivers, servo motors, programmable controllers, PLC modules, I/O modules, sensors, cylinders, pneumatic valves, compressed air processing units, industrial instruments, etc. The operating brands include: Bosch Rexroth, AVENTICS, Atos ATOS, Dipma DuploMATIC, B&R, Bentley Bently, Airtec Airtec, Seg ASCO, MooG, PARKER Parker, EATON VICKERS Eaton Vickers, Siemens and other imported brands. We sincerely welcome friends from all walks of life to call us for consultation, on-site inspection and business negotiation.- Name(chinese)

- Name(English)

- Shanghai Weimi Mechanical and Electrical Equipment Co., Ltd.

- China credit code

- Identity Verification

- Product Category

- Bosch REXROTH Hydraulic ComponentsAVENTICS Pneumatic Components

- Address

-

Shanghai Pudong New District, China

- Nearby port

- Shanghai

Shanghai Weimi Electromechanical Equipment Co., Ltd. is located in Jinqiao Yuzhou International, Pudong New District, Shanghai City. It is a trading company engaged in the management of foreign imported hydraulic and pneumatic spare parts and automated instruments; focusing on the field of industrial transmission automation fluids in China. The company adheres to the concept of integrity and service-oriented. Resolutely safeguard the interests of customers, protect the original products of our brands, provide customers with preferential prices, high-quality products and after-sales sales, achieve win-win cooperation, and create a good trade partnership. Our main products are solenoid valves, proportional valves, plunger pumps, pressure relays, pressure sensors, servo drivers, servo motors, programmable controllers, PLC modules, I/O modules, sensors, cylinders, pneumatic valves, compressed air processing units, industrial instruments, etc. The operating brands include: Bosch Rexroth, AVENTICS, Atos ATOS, Dipma DuploMATIC, B&R, Bentley Bently, Airtec Airtec, Seg ASCO, MooG, PARKER Parker, EATON VICKERS Eaton Vickers, Siemens and other imported brands. We sincerely welcome friends from all walks of life to call us for consultation, on-site inspection and business negotiation. -

Send your message to this supplier*From:*To:

Mr. Lei Qing

*Message:

Mr. Lei Qing

*Message:Inquiry

Copyright © 2003 - 2025 Goepe.com All rights reserved.